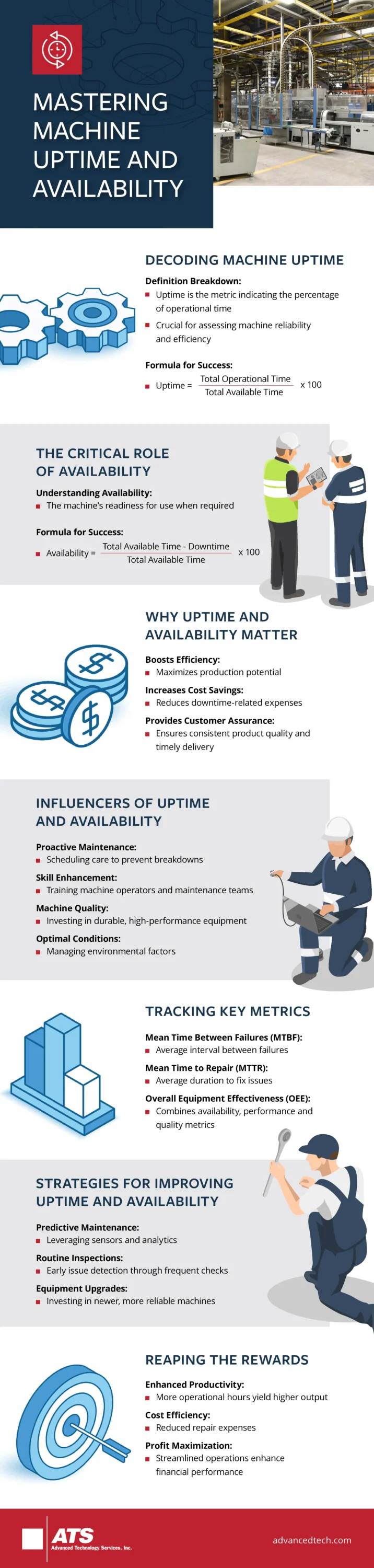

In manufacturing and industrial settings, machine uptime and availability are essential for maintaining productivity and minimizing disruptions. Optimizing these factors can significantly improve efficiency and reduce operational costs.

Machine uptime refers to the percentage of time equipment is operational and functioning correctly. Higher uptime means fewer interruptions and greater productivity. Achieving this requires proactive maintenance, skilled operators, and reliable equipment.

Availability, however, extends beyond uptime. It considers whether machinery is ready for use when needed, preventing production bottlenecks. This metric ensures seamless workflow, helping businesses meet deadlines and maintain quality standards.

Preventive maintenance is a key strategy in maximizing uptime and availability. Regular inspections help detect issues before they cause breakdowns. Additionally, skilled personnel play a crucial role in maintaining smooth operations by identifying and resolving potential problems promptly.

Investing in high-quality machinery also improves uptime. Reliable equipment experiences fewer failures and often includes advanced monitoring features. Environmental conditions such as temperature, humidity, and cleanliness further impact machine performance and should be properly managed.

Key performance metrics like Mean Time Between Failures (MTBF) and Mean Time to Repair (MTTR) help businesses track and improve machine reliability. Predictive maintenance, powered by sensors and data analytics, is another effective approach, allowing teams to address issues before failures occur.

By implementing proactive maintenance strategies, investing in quality equipment, and investing in industrial maintenance training for skilled personnel, businesses can enhance machine uptime and availability, leading to increased productivity and cost savings.